President John Garvey, accompanied by Senior Director of Capital Project Management Tom Mulquin, inspects the new high-efficiency chillers the University has installed in the Power Plant as part of CatholicU's extensive improvements to its heating and cooling infrastructure. In addition to producing savings from reduced utility costs, completion of the four-year project also supports the University's broader commitment to sustainability and good environmental stewardship.

Thanks to a three-phase project begun in 2016, the Catholic University campus is now running more smoothly and efficiently. Literally.

During winter months, the campus used to be dotted with steaming manhole covers, a visual symbol of the antiquated heating system used in many University buildings that was nearing the end of its useful life. Aged 30 years or more, many components of the system were older than most in the student body. Equipment often needed 24/7 operators to maintain basic operations, and the state of continuous repair and maintenance was costly to the University.

The Energy Project converted the steam-based system to a more efficient hot/chilled water system. The drastic renovation changes the energy distribution, improves efficiency at the Power Plant, and lowers operating costs.

The efficient chilled and hot water loop now reduces losses in heating and cooling. During the winter or heating season, hot water leaves the Power Plant at 160 degrees fahrenheit and comes back to the Power Plant at 130 degrees. During the cooling season or summer, chilled water leaves the Power Plant at 42 degrees and comes back to the Power Plant at 58 degrees. The reduction in cooling and heating losses saves the University in utility costs and helps it meet broader sustainability goals.

The project began and ended at the Power Plant. It started with the replacement of old steam boilers with high-efficiency hot water boilers and installation of a new central chiller plant. Then, the project snaked around campus with the installation of below-grade piping and utility lines to distribute utilities to all campus buildings. The goal was to improve heating and cooling of the buildings and renovate the Power Plant.

“We are very grateful for our partnership with our outside consultants and contractors on this extensive project; but even more importantly, we thank the University community for their extended patience with the disruptions in campus buildings and on the grounds,” says Debra Nauta-Rodriguez, associate vice president for Facilities and University Architect. “The project provides both environmental benefits and financial savings that serve us all.”

The new energy-efficient, state-of-the-art central heating water system includes 12 high-efficiency condensing boilers, variable flow distribution pumps, and an optimized control system. Direct buried and highly insulated steel piping with digital leak detection delivers hot and chilled water to campus buildings. Contractors installed 52,800 linear footage of heating and chilled water piping through campus to provide efficient cooling and heating.

The new central chiller plant produces and provides chilled water to most campus buildings, replacing numerous stand-alone chillers in buildings that currently are air-conditioned. In buildings that are not yet air conditioned, the connection to the new chilled water plant will enable air conditioning to be installed more easily over time and as funding allows. In the future, the Dining Commons and Conway School of Nursing will also connect to the chilled water plant. Designed to meet current standards for sustainable design, the new cooling system consists of three variable-flow centrifugal chillers, cooling towers with gray water usage, pumps, and new digital control systems.

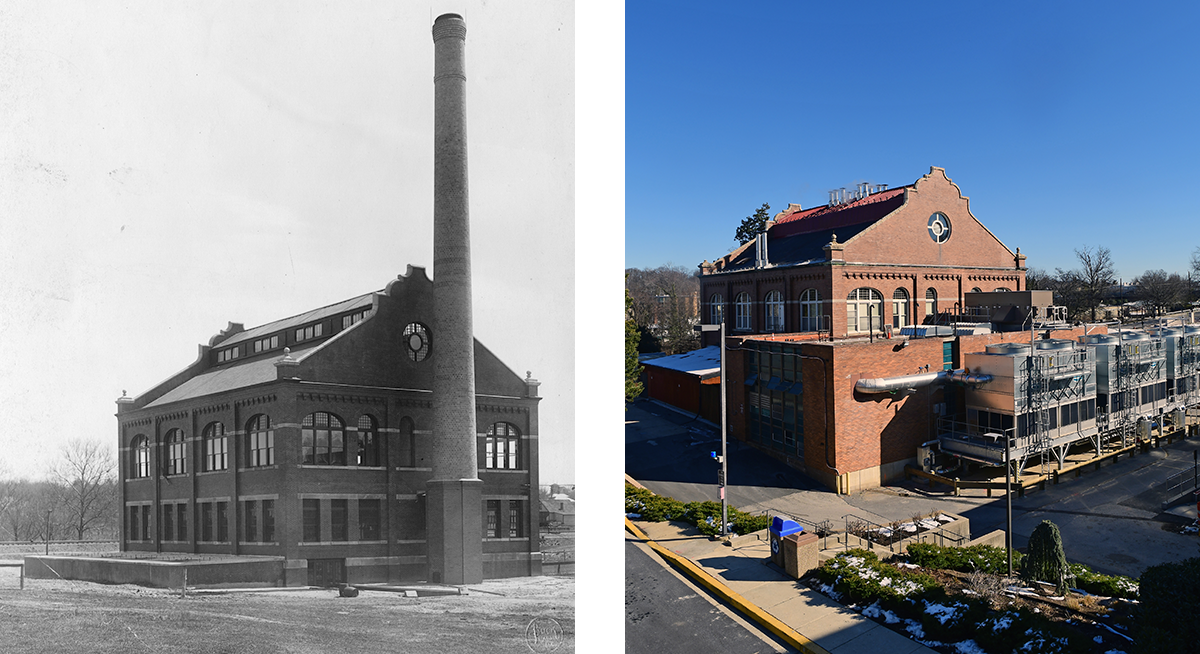

Left: The Power Plant in 1912. Right: The Power Plant today.

A stormwater harvesting cistern and filtration system collects rainwater, for use in three cooling towers. It can hold 15,000 gallons of water. The expected water savings are 270,226 gallons per year.

The Power Plant, originally constructed in 1910, houses the new modern heating water system and the new central chiller plant. The project includes new "smart" electrical infrastructure and system controls to support the new central heating and cooling systems. An energy-efficient emergency generator installed outside the Power Plant provides back-up power in the event of a loss of electricity on campus. The Energy Project also includes an autonomous system that continuously tracks the state of the machine as well as the system. Therefore, 24-hour operators are no longer required because the system gives live updates of the state of the machine from anywhere it is accessible.

Some buildings, such as Opus Hall and Father O’Connell Hall, have relatively new stand-alone modern heating and cooling systems; it was unnecessary to connect them to a central plant at this time. Also, a few buildings on north campus, such as the Raymond A. DuFour Athletic Center and the facilities ground center that have dedicated, high-efficiency hot and chilled water systems, will remain unconnected to the new utility loop for the foreseeable future. The system is designed to allow an increase of up to one million square feet of new space previously occupied by equipment that is now redundant.

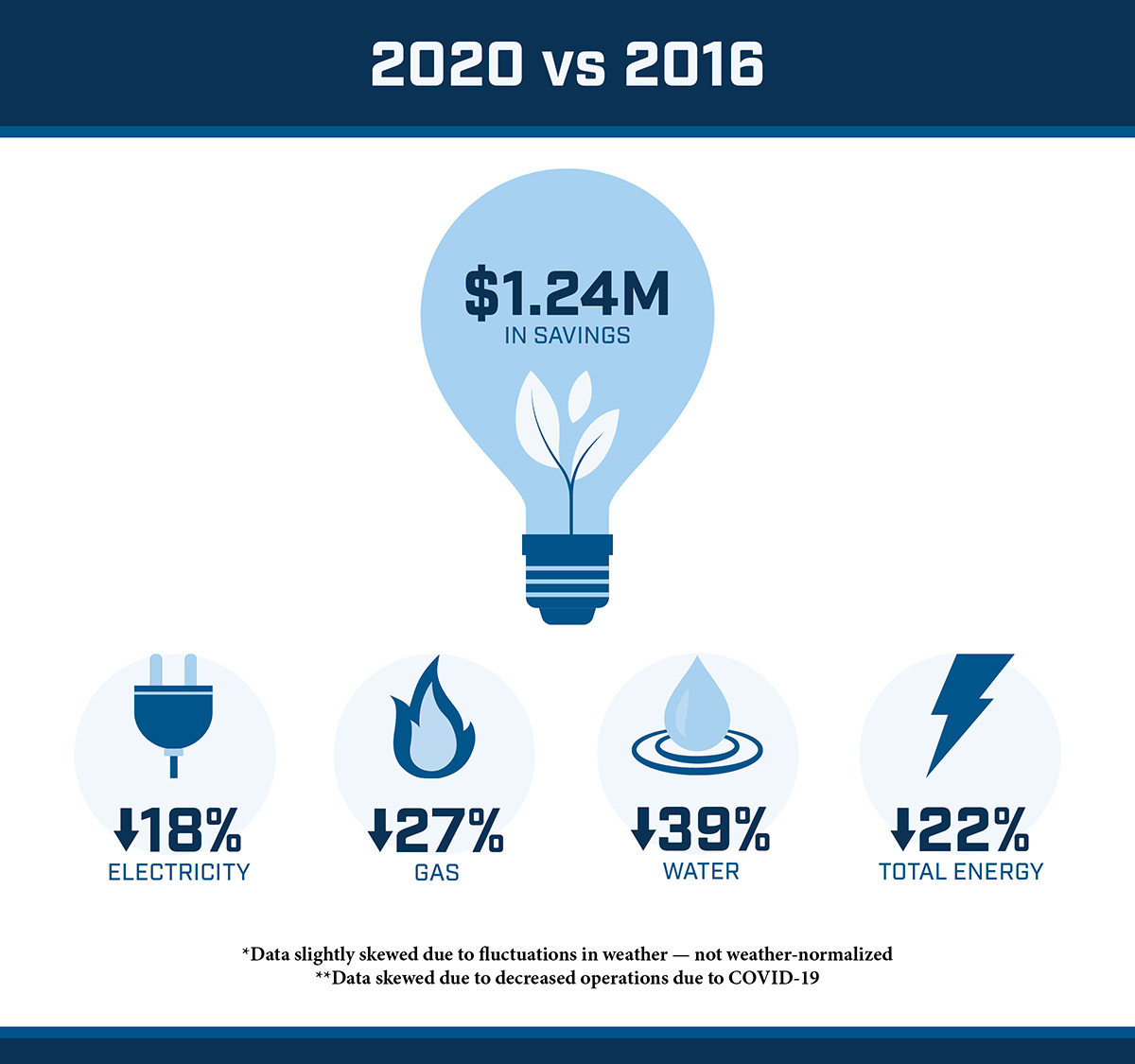

Original design estimates indicated that the new heating water system will save the University 10,401 million BTUs of natural gas each year. The chilled water system has the potential to save 616,478 kWh each year. Water conservation measures can conserve 7,093,482 gallons of water each year.

Whiting-Turner Contracting assisted the University in the construction management of the project. They will remain with the University for several more weeks to ensure everything is running smoothly. Whiting-Turner, engineering partner BKM, and Alexandra Harry, assistant director for campus facilities and sustainability initiatives, presented on the topic of campus energy at the recent International District Energy Association conference.